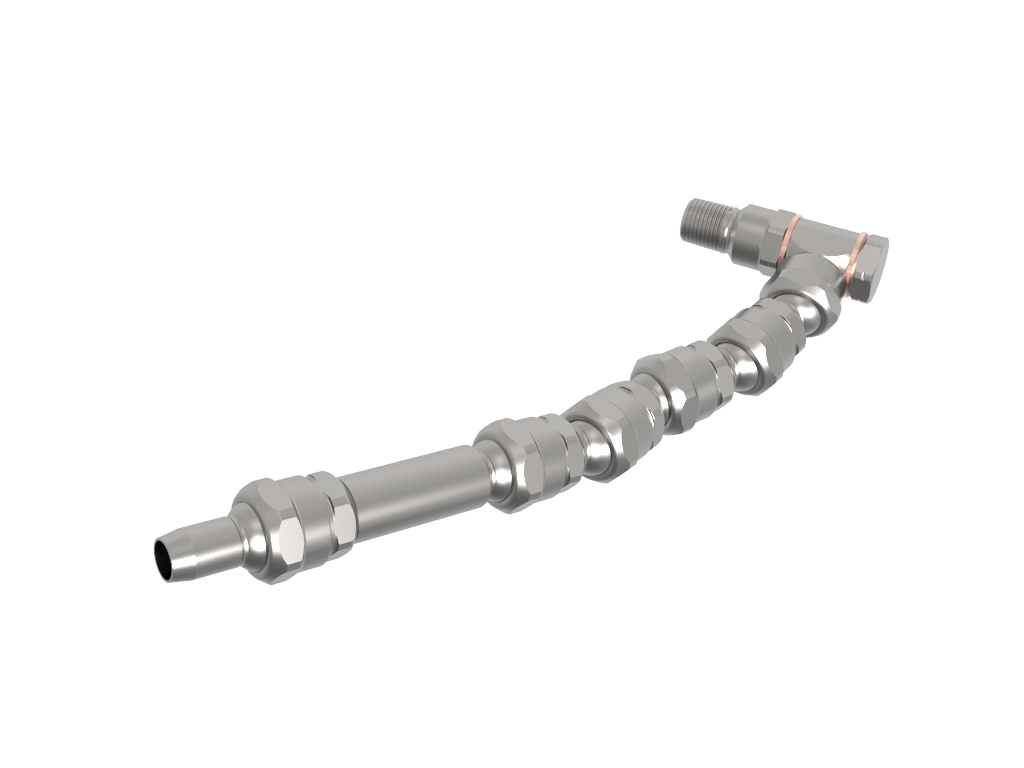

Articulated Steel Tubes

Coolant distribution systems with articulated steel tubes for machining with low, medium and high pressure / air blasting.

Coolant distribution systems with 4 different sizing programmes for low, medium and high pressure. Ideal for both CNC fixed and sliding headstock lathes, vertical and horizontal machining centers, grinding machines or transfer machines.

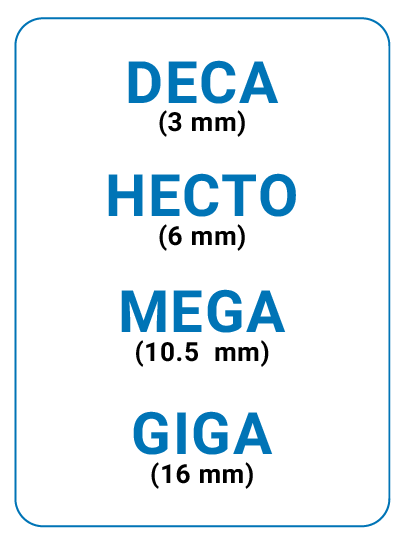

| PROGRAM | THROUGH HOLE | PRESSURE RATING |

|---|---|---|

| DECA | 3 mm | 150 Bar / 2175 psi |

| HECTO | 6 mm | 100 Bar / 1450 psi |

| MEGA | 10.5 mm | 80 Bar / 1160 psi |

| GIGA | 16 mm | 80 Bar / 1160 psi |

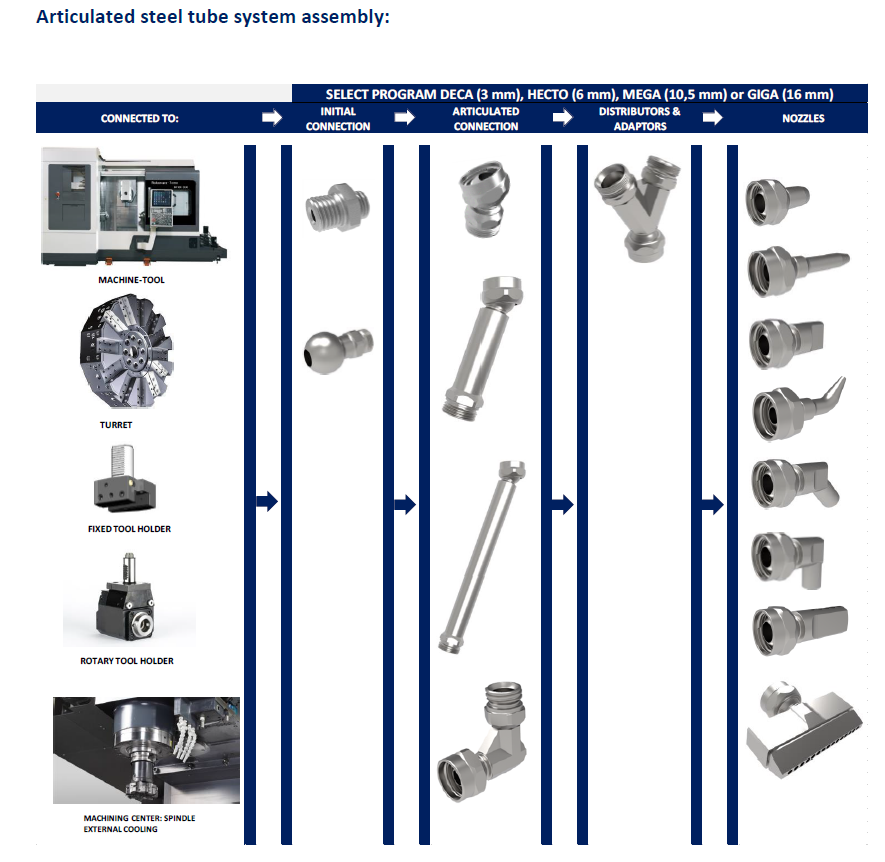

How to choose the Articulated Connection System?

FOLLOW THE STEPS BELOW:

STEP 1:

SELECT THE POINT OF INSTALLATION

- General cooling outlet in the Machine-tool

- Turret of a CNC lathe

- Stationary tool holder coolant outlet

- Driven tool holder coolant outlet

- External cooling outlet in a Machining centre

- Cooling outlet for grinding wheel in Grinding machines, etc.

STEP 2:

SELECT THE PRODUCT FAMILY

Select the product family according to the required flow rate and coolant pressure available.

STEP 3:

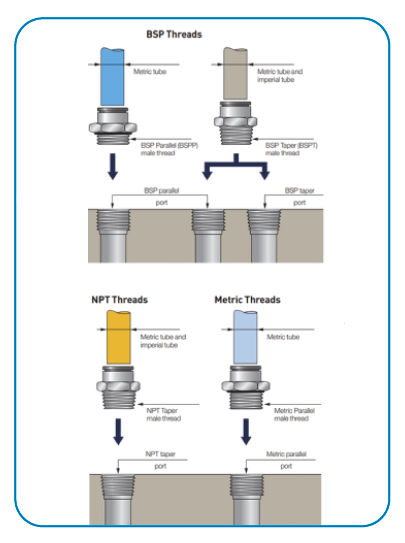

SELECT THE INITIAL CONNECTION

Identify the type of thread where the steel articulate tube system will be connected.

For example: BSPP 1/8", NPT 1/8", M8x1, BSPP ¼", etc.

STEP 4:

SELECT THE NUMBER OF ARTICULATED CONNECTIONS REQUIRED

According to the distance from the connecting outlet in the machine-tool, tool holder, etc. and the point where the coolant must be delivered.

STEP 5:

SELECT DISTRIBUTORS AND ADAPTORS (IF REQUIRED)

To make it possible to divide the refrigerant outlets.

STEP 6:

SELECT THE NOZZLE

Multiple nozzle designs to suit different coolant delivery requirements.

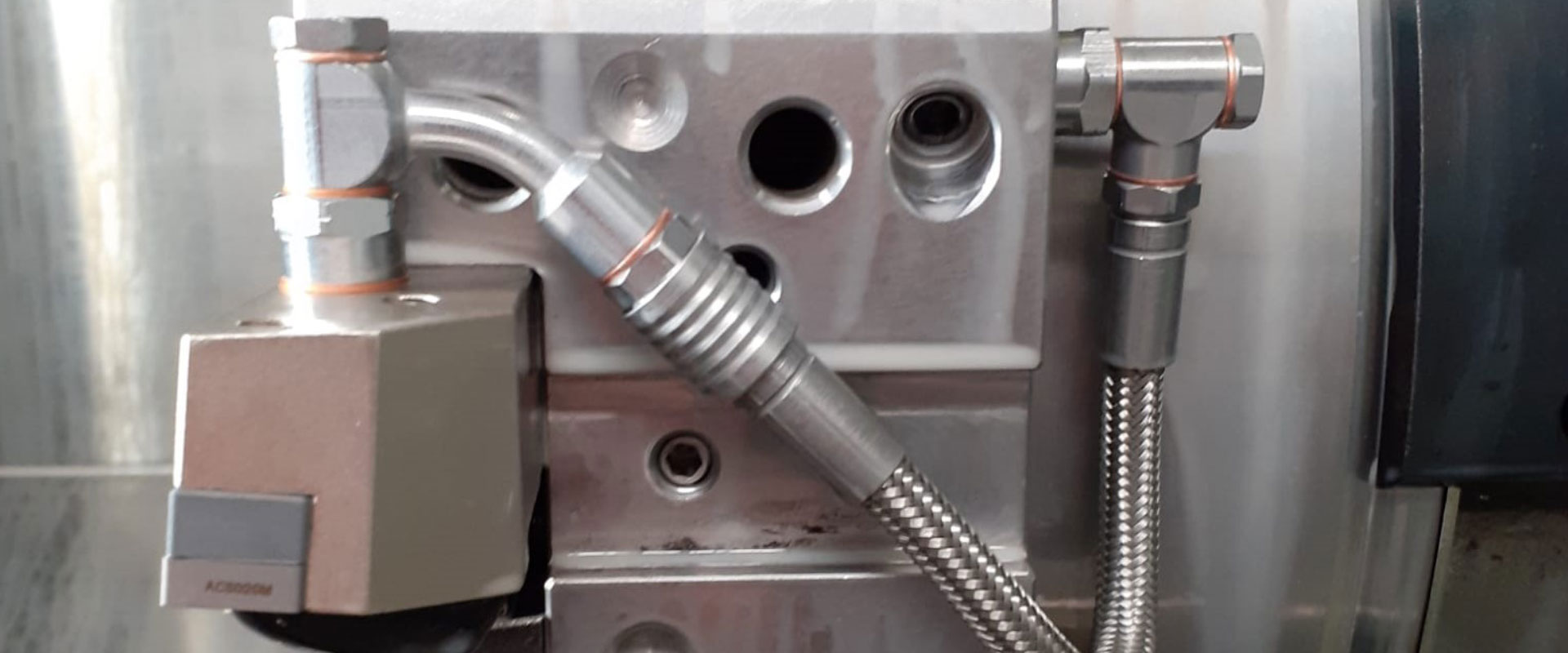

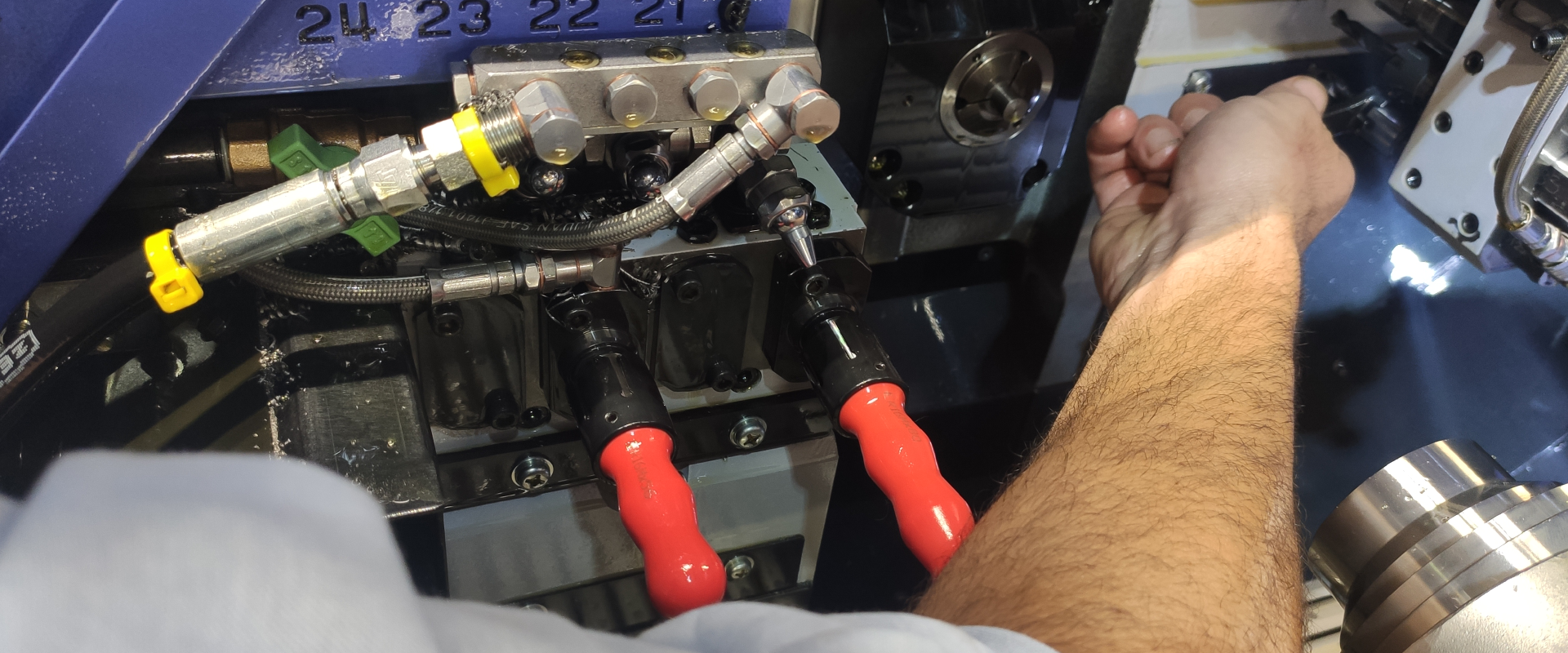

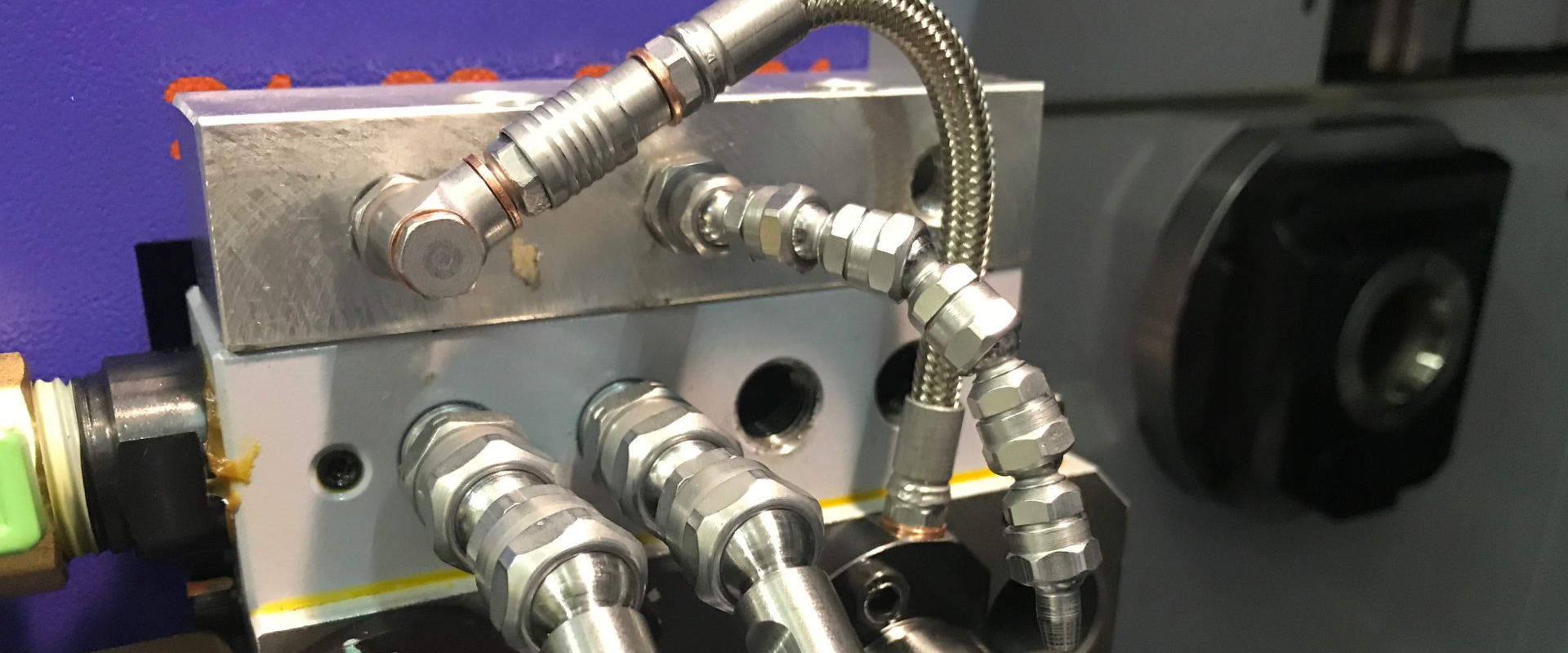

Distribution Systems

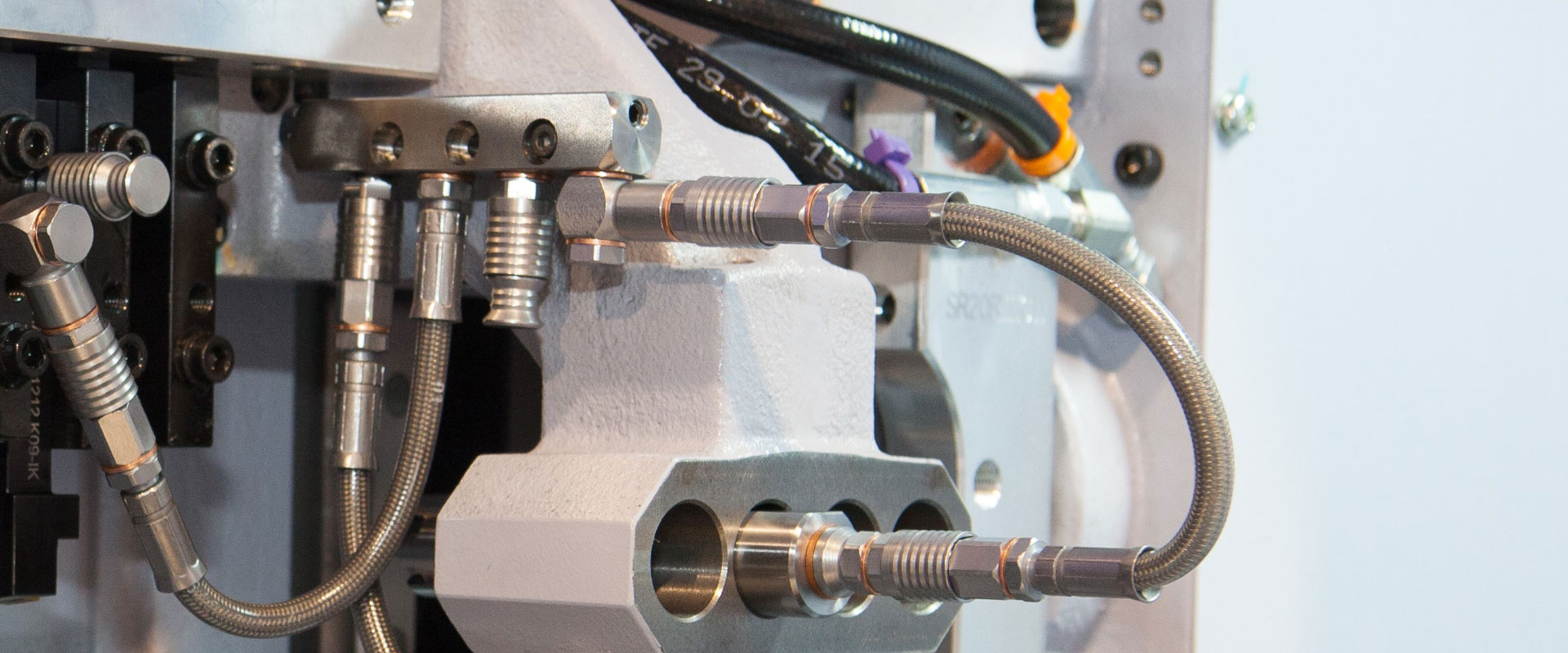

Coolant distribution systems with quick connection for medium and high pressure machining

Coolant distribution system with flexible tubes braided in stainless steel, quick connectors, copper tubes, adaptors and distribution blocks in 2 different size programs for medium and high pressure. Ideal for both sliding and fixed headstock CNC lathes, multi-spindle lathes or transfer machines.

| Item | MICRO Program | NANO Program |

|---|---|---|

| Minimum internal diameter of the program | 3.8 mm | 2.3 mm |

| Main program thread | M8x1 | M6x1 |

| Manufacturing material of components | Steel ZnNi | Steel ZnNi |

| Assembly wrench | SW11 | SW8 |

| Ideal for square tool shank dimension | 16x16, 20x20, 25x25 | 8x8, 10x10, 12x12 |

| Ideal for cylindrical tool shank dimension | Diameter ≥ 16 mm | Diameter < 16 mm |

| Ideal for collet holder dimension | ER-16 or bigger | ER-11 or bigger |

| External diameter of flexible distribution tube | 8 mm | 6.5 mm |

| Mínimum bending radius of flexible distribution tube | 30 mm | 15 mm |

| External diameter of cooper tube | 4 mm | 3 mm |

| Quick connector dimensions | OD: 13.5 mm L: 17 mm | OD: 9.8 mm L: 11.4 mm |

How to choose the Coolant Distribution System for Sliding Head Lathes?

(Widely used in Sliding headstock CNC lathes, but also in Fixed headstock CNC lathes, Multi-spindle lathes or Transfer machines)

FOLLOW THE STEPS BELOW:

STEP 1:

SELECT WHERE YOU WANT TO DO THE INSTALLATION

- COOLANT DISTRIBUTION BLOCK OR MACHINE'S OWN CONNECTION

- SCS COOLANT DISTRIBUTION BLOCK

STEP 2:

SELECT PRODUCT FAMILY

MICRO

(3.8 mm)

or

NANO

(2.3 mm)

Select according to the required flow rate, the available pressure and the size of the tools to be cooled.

STEP 3:

IDENTIFY THE NECESSARY THREAD TYPE OR BALL DIAMETER TO CONNECT TO THE BLOCK OR TO THE MACHINE

Identify the type of thread where to connect the coolant distribution system.

Example:

M6x1, M8x1, BSPP 1/8”, NPT 1/8”, etc.

STEP 4:

WHAT DO YOU WANT TO MOUNT ON THE SIDE OF THE CONNECTION TO THE BLOCK?

You can place a straight spacer, a 45° outlet (curved banjo) or a 90° outlet (banjo) and then connect a quick coupling, a flexible tube, a copper tube or directly these elements.

If the thread of the distribution block does not match the thread of the range of banjo bolts, quick release couplings, flexible tubes, etc., you can use the necessary adaptor.

If you fit a quick coupling, you can attach a flexible tube or a copper tube with the quick connection system.

STEP 5:

WHAT LENGTH OF TUBE DO YOU NEED?

Whether it is a flexible or copper tube, identify the required length.

In case of selecting a flexible tube, identify the necessary length to connect the coolant distribution block to the tool. Special lengths are available under request.

In case of selecting a copper tube to duct coolant from the distribution block to the cutting edge of the tool, then no additional parts are required.

STEP 6:

IDENTIFY THE TYPE OF THREAD ON THE TOOL SHANK

Identify the type of thread on the shank of the tool or tool holder.

Example:

M6x1, M8x1, BSPP 1/8”, NPT 1/8”, etc.

STEP 7:

WHAT DO YOU WANT TO MOUNT ON THE SIDE OF THE TOOL CONNECTION?

You can fit a straight spacer, a 45° outlet (curved banjo) or a 90° outlet (banjo) and then connect a quick coupling or attach the hose directly.

If the thread of the distribution block does not match the thread of the range of spacers, banjo bolts, quick release couplings or hoses, you can use the necessary adapter.

It must always include either on the connection side to the block or on the connection side to the tool at least one quick connection coupling.

STEP 8:

SELECT TYPE OF SEALING WASHERS

If sealing is required (fittings with parallel threads), you can select the washers of the required size and material: COPPER or ALUMINUM.

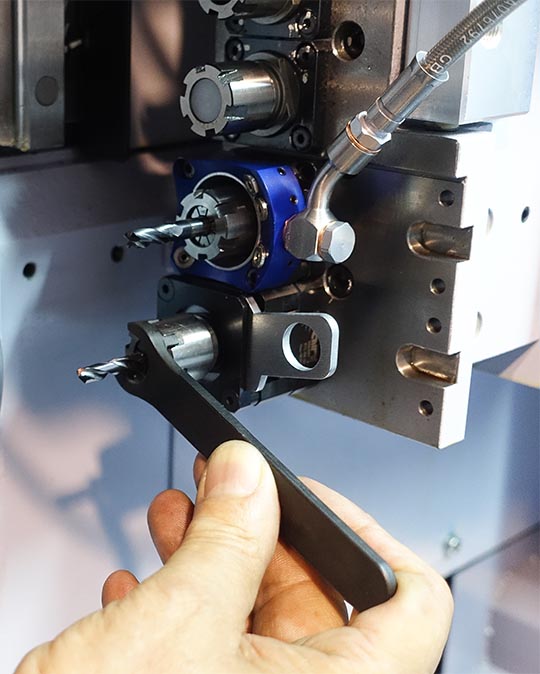

Safety and Productivity

Accessories to improve safety and productivity.

- Protective covers for ER type tool holders.

- Locking systems for safe tool change on driven tool holders.

- Extension tube for safe tool change in ER type tool holders.

- Coolant distribution rings for fixed and motorized tool holders.

- Tool protectors to avoid injuries while performing tool changes and accidental tool breakage during manipulation or storage.

- Protective covers to avoid coolant, chips or dirt ingress into driven or fixed tool holders with ER-collet clamping system, especially when mounted in the machine and not in use.

- Manual tool for accurate bending of coolant tubes.

- etc.

A set of elements that allow to increase productivity and safety in the preparation and operation of CNC lathes.

Machine Kits

Machine kits: pre-assembled sets ready to be mounted on machines or tool holders.

Kits for getting started and familiarising with the SCS Coolant Distribution System.

References delivered in a basic set for the most common applications.

Cookie preferences

Cookie preferences

.jpg)

.jpg)